At Plas-Tech Engineering, we understand that the quality of your molded part begins with the quality of your mold. This is especially critical if these molded parts are for medical or parenteral devices when patent safety is on the line. That’s why we specialize in building our own close-tolerance molds and work with various commodity and engineering-grade materials. We maintain full design control over all our tooling to ensure optimized performance with our inventory of electric mold presses.

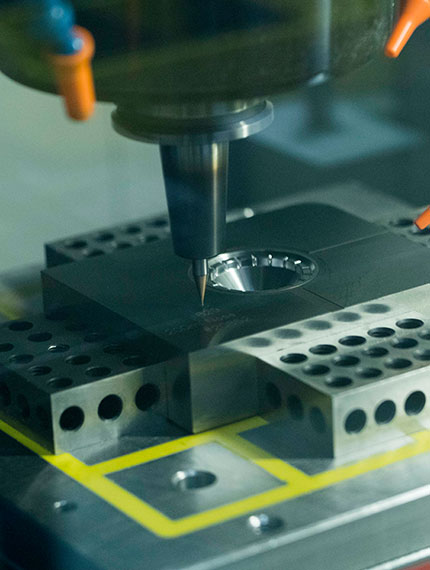

We installed a new tool room in 2014 and continue to update it with state-of-the-art technology in order to keep 24-hour machining for lights-out efficiency and quick turn-around times. Whether you need a simple or complex mold, we have the expertise and the equipment to deliver it with high quality and precision.

One of the features that sets us apart from other mold manufacturers is our capability to build molds for Scientific Injection Molding (SIM). SIM is a process that uses sensors and data to monitor and control the molding variables, such as pressure, temperature, flow rate, and viscosity. By applying SIM principles, we can ensure consistent and repeatable results for every part we produce.

To achieve SIM, we use Kistler transducers in our molds. These are devices that measure the cavity pressure and transmit the signals to the molding machine. Kistler transducers help us optimize the molding process, detect any defects or variations, and reduce waste and energy consumption. With Kistler transducers, we can guarantee the highest level of quality and accuracy for your molded parts.

We offer a wide range of tooling options to meet your specific molding requirements and expectations. Our tooling options include, but are not limited to:

- Multi-Colored & Multi-Component Molds

- Rotating Platen Tooling

- Overmold Tooling

- Micro-Mold Tooling

- Hot Runner Tooling

- In-Mold Labeling & In-Mold Decoration (IML/IMD)

- Stack Molds

- Glass Alternative or Replacement Molds

- Insert Mold Tooling

- Collapsible Core, or Expandable Core Molds

- Unscrewing Molds

- Tooling Amortization Programs

- Unit and Insert Stacks in PTE Molds