Plas-Tech Engineering is a leading provider of custom plastic injection molding and contract manufacturing services for the medical device industry. We have over 25 years of experience in designing, developing, and producing high-quality medical devices that meet the stringent requirements of the FDA and other regulatory agencies. We also offer comprehensive sterilization solutions for medical devices, including Gamma, X-Ray, EtO, and other sterilization methods. Plas-Tech Engineering has the knowledge, skills, and resources to manage the sterilization process from start to finish, ensuring the safety, efficiency, and quality of the medical devices.

Plas-Tech Engineering can manage various sterilization methods for medical devices, depending on the device type, material, and intended use. Some of the most common sterilization methods that we are capable of are:

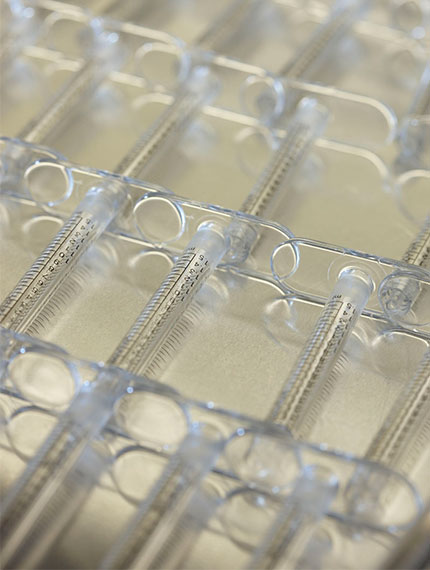

- Gamma Irradiation: This method uses high-energy gamma rays to destroy microorganisms on the surface, and inside the medical device. Gamma irradiation is suitable for devices that are sensitive to heat and moisture, such as syringes, catheters, and implants. Plas-Tech Engineering works with certified gamma irradiation facilities to ensure the proper dose, validation, and documentation of the sterilization process.

- X-Ray Irradiation: This method uses high-energy X-rays to kill microorganisms on the penetration depth and higher dose rate. X-Ray irradiation is ideal for devices that have complex geometries, such as stents, valves, and pacemakers. We collaborate with qualified X-ray irradiation providers to ensure the optimal sterilization conditions and results.

- EtO Sterilization: This method uses ethylene oxide gas to sterilize the medical device. EtO sterilization is effective for devices made of plastic, rubber, or metal, that have lumens, cervices, or pores. EtO sterilization is also compatible with devices sensitive to radiation, such as electronics, sensors, and optics. Plas-Tech Engineering partners with accredited EtO sterilization facilities to ensure compliance, safety, and quality of sterilization process.

- Other Methods: Plas-Tech Engineering can also manage other methods of sterilization for medical devices, such as steam, hydrogen peroxide, ozone, and plasma. Plas-Tech Engineering can help select the best method for each device, based on the device specifications performance, and biocompatibility. We can also assist with the validation, verification, and documentation of the sterilization process, according to the relevant standards and regulations.

Plas-Tech Engineering is a trusted partner for medical device manufacturers who need reliable and efficient sterilization solutions for their products. Plas-Tech Engineering can manage various sterilization methods for medical devices, including Gamma, X-Ray, EtO and other methods of sterilization. Plas-Tech Engineering has the expertise and experience to ensure the safety, efficacy, and quality of the medical devices, while meeting regulatory agency and customer expectations. Plas-Tech Engineering is committed to delivering excellence and innovation in every project, from design to delivery.