At Plas-Tech Engineering, we are committed to delivering high-quality products and services that meet or exceed the expectations of our customers and regulatory authorities. We have established a robust quality management system (QMS) that complies with international standards and regulations for medical device manufacturing.

We are proud to be;

- ISO 13485 Certified: This certification demonstrates our ability to produce and deliver medical devices and related services that consistently meet customer and regulatory requirements.

In addition, we have implemented a comprehensive quality assurance program that covers every stage of our production process, from raw material selection to final product delivery.

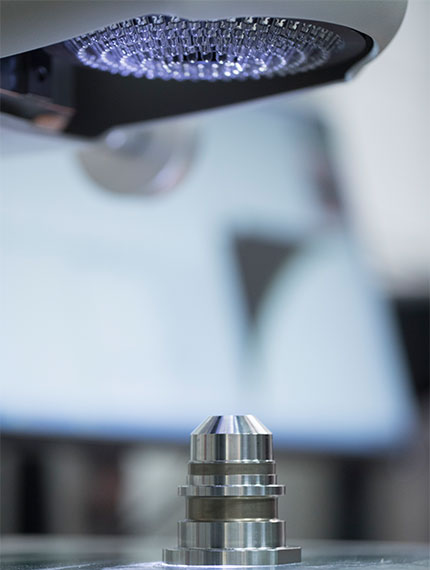

We have invested in state-of-the-art equipment and technology that enable us to perform accurate and reliable measurements, inspections, and validations. Our quality assurance program features include;

- Internal Metrology and Calibration: Our dedicated metrology lab performs regular calibration and verification of our measuring instruments and equipment, ensuring accuracy and traceability. We also use independent labs to verify our calibration results and to conduct correlation studies with our customers to reduce the chances of a false-positive.

- Scalable Quality Inspection Equipment: To meet any customer demands, we have a variety of inspection equipment that can handle any size, shape, or complexity of products. These include Coordinate Measuring Machines (CMM), Optical Comparators, Vision Systems, and Microscopes.

- Inspections: At every stage of our production process, thorough inspections are done. These include:

- Incoming Inspections: This process verifies the quality and specifications of the raw materials and components that we receive from our suppliers.

- Manufacturing and In-Process Inspections: This is where we monitor and control the quality and consistency of our manufacturing processes, such as injection molding, assembly, and packaging.

- Finished Goods Inspection: The final inspections and tests are performed on our products before they are shipped to our customers.

- Validations (IQ/OQ/PQ): We offer validation master planning (VMP) of our production process to ensure their suitability, effectiveness, and repeatability. They include the following:

- Equipment: We validate the installation, operation, and performance of our equipment, including our injection molding machines, assembly machines, and packaging machines.

- Process: We validate the parameters, methods, and outcomes of our production processes in injection molding, assembly, and packaging.

- Software: We validate the functionality, reliability, and security of our software systems, including Enterprise Resource Planning (ERP), Quality Management System (QMS), and Computer-Aided Design (CAD).

- Method: We also validate the accuracy, precision, and robustness of our measurement and testing methods, including dimensional, functional, and biocompatibility tests.

In addition to our quality assurance program, we adhere to the highest standards of cleanliness and hygiene in our production environment. Our cleanroom facility complies with the ISO Class 6, 7, and 8 requirements, ensuring our products are free from any contamination or foreign particles. We follow strict policies, procedures, and change processes that are aligned with the 21 CFR Part 820 regulations that ensure our QMS is well-documented, controlled, and audited.

As a global supplier of plastic injection molding and medical device manufacturing services, we support our customers with their regulatory submissions, such as 510(k) for the US market and CE marking for the European market. We have the experience and expertise to assist our customers with the technical documentation, risk management, and conformity assessment procedures necessary for demonstrating the safety and effectiveness of their products.

As not only a plastic injection molding and medical device manufacturing company, but also a quality and regulatory partner for our customers, we strive to provide products and services that meet the highest standards of quality, safety, and efficiency. We aim to satisfy the needs and expectations of our customers and regulatory authorities.

Contact us today to learn more about our quality and regulatory capabilities, and how Plas-Tech Engineering can help you with your plastic injection molding and/or medical device manufacturing projects.